|

This document is intended

for A-100 users who want to learn a little bit about the technical

details of the A-100. We will start with some electronic basics and

introduce at first the most important electronic parts used in the A-100

circuits. Then we will show how some basic circuits (like attenuators,

amplifiers, mixers, inverters and so on) can be realized with these

parts. The following paragraph will show some simple modifications of

A-100 modules: e.g. changing the sensitivity of CV or audio inputs,

increasing or decreasing output levels (e.g. VCAs or mixers with maximum

amplification > 1), adding offset feature to mixers, changing between

DC and AC coupled inputs/outputs, adding feedback inserts for VC

resonance to all filters and many more.

This page starts September 2004. New items will be added little by

little. If you have any suggestion for this page please send your ideas

to hardware@doepfer.de. We will

try to fulfil all wishes, providing they are possible and will not

contain confidential information.

Additional information about

technical details (e.g. CV/gate control principles, A-100 bus, A-100

power supply) and mechanical details (frontpanel measures, A-100 frame

concept) is available in these documents:

The A-100 service manual is

available only for A-100 customers (see price

list for current price). The words -

mainly building, testing and adjustment notes for the manufacturer - are

in German but the schematics, silk screen and bill of material are

international.

Other pages of interest for

DIY:

|

|

|

|

|

1. Electronic Parts

(For some parts different signs are shown. Normally the left one is used

in USA or Japan, the right one in Germany or Europe)

|

|

|

|

Fixed resistors

A resistor is determinded by

these parameters:

-

value (... Ohm, ...

kOhm, ... MOhm, usual abbreviations kOhm = k and MOhm =M, e.g. 2.2

kOhm = 2.2k or 2k2)

-

power (.. mW, ...W)

-

tolerance (%)

-

max. voltage

-

dimensions (e.g. length,

diameter and especially the grid between the legs on the pc board)

In the A-100 normally only

resistors with 1/4W (250mW) and 5%, 1% or 0.1% tolerance are used. For

the value and tolerance of a resistor normally a color code is used

(should we add the color code at this place ?).

|

|

|

|

Potentiometers

Potentiometers are available

as rotary potentiometers or fader types. Normally, a potentiometer has 3

terminals: two end terminals and a slider terminal (upper picture). The

slider touches a resistance surface that is located between the end

terminals. Sometimes the second end terminal is not shown (lower

picture) if only one end terminal is required, e.g. if the part works

only as a variable resistor rather than a voltage divider.

A potentiometer is

determined by these parameters:

-

value (... Ohm, ...

kOhm, ... MOhm)

-

power (.. mW, ...W)

-

tolerance (%)

-

characteristics (law)

-

mechanical dimensions

(e.g. diameter, type, length and material of the axis, distance and

diameter of the holes required on the pc board, position of

auxiliary terminals without electronic function and so on)

The characteristics -

sometimes even called law - is a very important parameter of a

potentiometer. This parameter describes the connection between the

rotary angle (resp. fader position for fader potentiometers) and the

resistance value between terminal 1 and slider terminal. Typical

characteristics are linear, logarithmic and inverse logarithmic.

Sometimes special characteristics are used (e.g. S-type law) but these

are not very common. For audio attenuation normally logarithmic

potentiometers are used as the human ear senses the loudness of an audio

signal in a logarithmic way too. The same applies to potentiometers that are

used to control time parameters (e.g. attack/decay/release time of an

envelope generator). For attenuation of control signals normally linear

potentiometers are used. For special functions inverse logarithmic

potentiometers are used (e.g. resonance/emphasis control in filter

circuits).

Another special type is a stereo potentiometer: two potentiometers with

one common axis. The values for the two potentiometers vary in the same

way. Used e.g. for manually controlled filters or stereo applications.

Other special types of potentiometers are not described here (e.g. dual

potentiometers with 2 concentric axis, or potentiometers with additional

terminals) as they are not used in the A-100.

A very special circuit is a

so-called vactrol. This is a combination of a light depending

resistor (LDR) and LED both put into a small 100% light-proof

case. For details please refer to the vactrol

document.

|

|

| front view |

rear view |

| Potentiometers

used in the A-100 |

The above pictures shows the

type of potentiometers used in the A-100 system. These potentiometers

are equipped with a mounting bracket that increases the mechanical

stability. For most of the A-100 modules the potentiometers (together

with the sockets) are used to mount the pc boards to the front panels.

The A-100 potentiometers are available as spare parts with these values:

10K (A and B), 50K (A, B and C), 500k (B), 1M (A and B) with A =

logarithmic (audio type), B = linear and C = inverse logarithmic

(ususally for filter resonance controls used). For prices please look at

the price list.

|

|

|

|

Trimming potentiometers

The electronic function of a

"normal" potentiometer and a trimming potentiometer is the

same. The only difference is the mechanical appearance: trimming

potentiometers are normally much smaller and have a very short axis that

is adjusted with a screw driver. Trimming potentiometers are used to

adjust parameters that have to bet set once at the factory and that are

normally not controlled by the user (e.g. offset frequency and scale of

a VCO, maximum/minimum limitation of values, adjustment of click/pop

feedthrough of sound processing devices like VCA, VCF, ring modulator,

frequency shifters and so on). Sometimes users replace trimming

potentiometers with normal ones to have access to such additional

parameters.

Trimming potentiometers are available normally only linear.

Apart from that they are defined by the same parameters as normal

potentiometers.

|

|

|

|

Capacitors

A capacitor is determinded

by these parameters:

-

value (... pF/picofarad,

... nF/nanofarad, ... uF/microfarad, usual abbreviations pF =p, nF

=n, uF =u, 2.2 nF = 2.2n or 2n2)

-

type of dielectric

(foil, ceramic, multilayer, electrolytic)

-

tolerance (%)

-

max. voltage

-

polarized/non polarized

(electrolytic capacitors are normally polarized)

-

dimensions (e.g.

length/width/height or length/diameter and especially the grid

between the legs on the pc board)

In the A-100 all types of

capacitors are used. Value, voltage and tolerance are normally written

as normal characters on the component (e.g. 4n7 63V). But even color

codes and number codes are used (e.g. 103 means 10x1000=10000).

Sometimes it is difficult to find the value of a capacitor. E.g.

"100" without additional pF/nF could mean 100pF or 100nF. Some

experience is required to find out the correct value if the declaration

on the component is not readable, or complete. To be certain of a

capacitors value, one could use a capacitor

measuring instrument such as a multimeter with capacitor measuring

option.

So-called electrolytic

capacitors are used for values of 1uF and more as the other types of

capacitors would be too large. Normally electrolytic capacitors are

polarized (i.e. one has to pay attention to positive and negative

terminal of the part). If there are "+" or "-" signs

in a schematic this means that an electrolytic capacitor is used. The

three examples on the left with "+" and "-"

signs denote an electrolytic capacitor.

Other types of capacitors

(e.g. variable capacitors) are not used in the A-100.

|

|

|

|

Diodes

Electronic part that works

as one-way for electric current. The triangle terminal (left) of the

symbol is the positive side (or anode), the single vertical line (right)

is the negative terminal (or cathode). Used e.g. for clipping,

rectifying or overvoltage protection. Even light emitting versions (LED)

available in different colors (red, green, yellow, orange, blue, white).

In this case the brightness is approximately proportional to the

current.

A very special circuit is a

so-called vactrol. This is a combination of a light depending

resistor (LDR) and LED both put into a small 100% light-proof

case. For details please refer to the vactrol

document.

|

|

|

|

Transistors

Different types of

transistors are available, e.g. bipolar npn or pnp, field effect (FET).

A transistor can be used with the suitable circuit (i.e. with additional

resistors and capacitors) e.g. as amplifier, switch or current source.

|

|

|

|

Operational Amplifiers

Operational amplifiers are

special integrated circuits that make available a standard amplifier

with 2 inputs (inverting and non-inverting input) and high amplification

(typ. > 1000). Circuits with one, two or more opamps

(abbreviation for operational amplifier) are available. The following

table shows the pin-out of the most popular types of single, dual and

quad opamps.

|

Single type

e.g. uA741, TL061, TL071, TL081,

TLC271, NE5534, LF411, LF351, LF356 |

|

Dual type

e.g. uA747, LM1458, LM4558,

TL062, TL072, TL082, TLC272, NE5532, LF412, LF353 |

|

Quad type

e.g. LM124, LM224, LM324, TL064,

TL074, TL084, TLC274, LF444 |

The power supply pins

(marked with the "+" and "-" triangles) of the integrated circuit

in question have to

be connected to +12V and -12V for A-100 applications. In schematics the power

supply pins of opamps are often omitted. The left opamp symbol includes the

power supply pins. The right symbol is without the power supply pins.

Unused OpAmps (if e.g. only 3 devices of a quad opamp are used) have to

be terminated in this way: non-inverting input has to be connected to

GND, inverting input and output have to be connected (directly or even

via resistor in the 1k...100k range).

|

|

|

|

Switches

A lot of different switches

are available. There exist different distinguishing marks,

e.g.:

The pictures show from top

to bottom the symbols for a simple on/off switch (SPDT with one ON

contact only) , a change-over switch (SPDT with two ON contacts), a

rotary switch with 3 positions, a change-over switch with middle

position (SPDT with ON-OFF-ON) and a rotary switch witch 5 positions.

|

|

|

|

Jack sockets

Standard sockets used in the

A-100 for all inputs and outputs. Provided that a plug is inserted into

the socket the GND and tip terminals of the plug are connected to the

corresponding terminals of the socket. The tip is normally the

"hot" pin, i.e. the terminal leading the CV resp. audio

signal. The sockets are equipped with switching contacts (the arrow in the symbol).

Both the GND and tip terminal are switched but only the switching

feature of the tip terminal is used in some A-100 modules. Provided that no plug is

inserted into the socket the switched tip contact (arrow terminal in the

left symbol) is

connected to the "normal" tip contact (the terminal represented by the

horizontal line in the left symbol). As soon as a plug is inserted this connection is

interrupted and the signal at the tip of the plug is connected to the

tip terminal of the socket. This feature can be used for default connections

(i.e. connection within a module that is established provided that no

plug is inserted into the corresponding socket). Example: internal

default connections of the A-109 signal processor.

This function is often called "normalling" or

"normalizing".

|

|

| rear view |

front view |

| jack

sockets used in the A-100 |

The above pictures show the

type of jack sockets used in the A-100 system. For most of the A-100

modules the sockets (together with the potentiometers) are used to mount

the pc boards to the front panels. The A-100 sockets are available as

spare parts. For prices please look at the price

list.

|

|

|

|

Power Supply

For each circuit, a power

supply is required. The three symbols to the left side denote +12V, -12V and

GND. Some circuits may require no power supply (e.g. multiples or the simple

attenuator below) or only a positive supply. All circuits that use

operational amplifiers require all three +12V, GND and -12V. Some

modules even require +5V (mainly "digital" modules with

digital circuits - like microprocessors, memories, or logic circuits -

which often require a +5V power supply).

|

|

|

2. Basic circuits

|

|

|

|

Simple attenuator

This is a simple passive

attenuator (i.e. no power supply required). J1 is the input socket, J2

the output socket. A typical value for P2 is 10k...100k. A linear or

logarithmic type can be used for P2 (logarithmic especially for audio

applications as the loudness characteristics of the human ear is approx.

logarithmic).

|

|

|

|

Simple lowpass

This is a simple passive

lowpass with 6dB/octave slope. A non-inverting amplifier can be added at

the output (and even at the input) to make the circuit independent of

input/output impedance (i.e. the "loads" connected to J1 resp.

J2). Replacing of R1 by a vactrol leads to simple voltage controlled

lowpass filter. Replacing R1 by a potentiometer leads to a simple

manually controlled lowpass filter

Frequency of the lowpass: f

= 1/(2 * Pi * R1 * C1) with Pi = 3.14

Example: R1 = 47kOhm, C1 = 10nF -> f ~ 340 Hz

|

|

|

|

Simple highpass

This is a simple passive

highpass with 6dB/octave slope. A non-inverting amplifier can be added

at the output (and even at the input) to make the circuit independent of

input/output impedance (i.e. the "loads" connected to J1 resp.

J2). Replacing of R1 by a vactrol leads to simple voltage controlled

highpass filter. Replacing R1 by a potentiometer leads to a simple

manually controlled highpass filter

Frequency of the highpass: f

= 1/(2 * Pi * R1 * C1) with Pi = 3.14

Example: R1 = 10k, C1 = 2,2n -> f ~ 7.2 kHz

|

|

|

|

Non-inverting amplifier

This is a simple

non-inverting amplifier: The term "non inverting" means that

the polarity of input and output signal are the same. In other words: a

positive input signal applied to J1 will cause a positive output signal

at J2 and a negative input signal applied to J1 will cause a negative

output signal at J2.

The amplification of this

circuit is 1 + R1/R2.

Example 1: R1 = 0 Ohm (connection), R2 omitted -> A = 1

Example 2: R1 = 47k, R2 = 47k -> A = 2

Example 3: R1 = 100k, R2 = 10k -> A = 11 If

R1 or R2 is replaced by a potentiometer the amplification can be

adjusted. If e.g. R1 in the last example is replaced by a 100k

potentiometer the amplification is adjustable in the range 1...11. This

circuit can be used to built an simple amplifier if the desired audio or

CV signal is too small for a certain application. Attention ! The minimum

amplification of this circuit is 1 (no real attenuation possible

provided that no external attenuator is used).

|

|

|

|

Inverting amplifier

This is a simple inverting

amplifier: The term "inverting" means that the polarity of

input and output signal are opposite. In other words: a positive input

signal applied to J1 will cause a negative output signal at J2 and a

negative input signal applied to J1 will cause a positive output signal

at J2.

The amplification of this

circuit is - R2/R1 (" - " indicates the opposite

polarity of input and output)

Example 1: R1 = R2 = 47k -> A = - 1

Example 2: R1 = 10k, R2 = 100k -> A = - 10

If R2 is replaced by a potentiometer

the amplification can be adjusted. If e.g. R2 in the last example is

replaced by a 100k potentiometer the amplification is adjustable in the

range 0...-10. This circuit can be used to built an simple (inverting !)

amplifier if the desired audio or CV signal is too small for a certain

application.

The minimum amplification of

this circuit is zero (if R2 = 0). To obtain a non-inverted output

another inverting amplifier with amplification - 1 has to be used.

The inverting amplifier can

be extended by adding more input sockets (J1) and corresponding input

resistors (R1). The right terminals of all input resistors are connected

to the inverting input (-) of the operational amplifier O1. The relation

between the corresponding input resistor R1 and R2 (the same for all

inputs) defines the sensitivity of the input in question. If all

resistors have the same value (e.g. 100 kOhm) the amplification is

"1" for all inputs. Lowering R1 (e.g. 47k or 22k) increases the sensitivity of

the input in question. Increasing R2 (e.g. 220k or 1M) increases the amplification resp.

sensitivity for all inputs simultaneously.

The minus terminal of the operational amplifier is often called

"virtual GND" in this circuit as the voltage measured at this

point is very close to GND within a few millivolts - independent of the

incoming voltages! The

first circuit example (chapter 3: "CV mixer with offset

function") shows a typical application of inverting

amplifiers with several inputs.

|

|

|

|

Voltage clamping /

limiting / clipping

This is a circuit that

limits an incoming voltage to the range U1-UD2 ... U2+UD1. The voltage

U1 has to be less than U2. UD1 and UD2 are the forward voltages of the

diodes D1 and D2. To keep these voltages as small as possible Schottky

diodes (e.g. BAT42) ore germanium diodes are recommended because their

forward voltages are in the 0.2...0.3V range. R works as a serial

protection resistor. A typical value for R is 1k.

A typical application is the

limitation of an analog voltage to 0...+5V (e.g. for the inputs of Pocket

Electronic or USB64). In this case U1 is

connected to GND and U2 to +5V. Another

application is sound distortion by voltage clipping. If U1 and U2 are

variable voltages (e.g. outputs of operational amplifiers of one of the

circuits in this document) the clipping levels can be voltage controlled

too.

|

|

|

|

|

3. Circuit examples

|

|

|

|

Mixer with optional

offset function and inverted/non-inverted outputs

Inputs J1 ... J3 are

standard inputs.

Input J4 has offset function provided that no plug is inserted into J4

as the switching contact of J4 is connected to the positive supply

voltage in this case (via the protection resistor R8). At

J5 the inverting sum of all inputs is available. J6 outputs the

non-inverting sum. P5 allows an additional attenuation of the complete

signal (affects only J6).

Typical values for the parts

used:

O1, O2 = LM1458, TL082, NE5532

P1...P4 = 47k linear (CV) or log (audio)

R1...R7 = 100k (for overall amplification 1)

To obtain a higher overall amplification R5 has to be increased (e.g. to

220k for overall amplification ~ 2 or to 1M for overall amplification ~

10).

The value of R8

defines the offset range (about 0...+6V for R8=33k, a lower

value of R8 will increase the offset range and vice versa). |

|

|

|

Matrix Mixer

|

Matrix Mixer

The CV mixer described above

can be expanded to a so-called matrix mixer. This circuit has several

inputs available (three in the example circuit) that can be mixed to

different outputs (three in the example circuit) with adjustable levels.

At each point of the matrix a potentiometer is available that defines

the level for the matrix junction in question. The

circuit can be used for CV or audio applications. The number of inputs

and outputs can be increased to the desired value of columns and rows.

For each of the outputs the two OpAmp circuit with the corresponding

output socket is required. For each input another socket and the

corresponding quantity of potentiometers and resistors is required.

Typical values for the parts

used:

All operational amplifiers: LM1458, TL082, NE5532

All potentiometers: 47k linear (CV) or log (audio)

All resistors: 100k

To obtain a higher or smaller overall amplification the feedback

resistor of the first (left) OpAmp of each output circuits has to be

adjusted (as described above).

It is recommended to use a

separate pcb for the output circuits. The input sockets and matrix

potentiometers/ resistors can be wired by hand very easily.

|

|

|

|

Matrix Mixer II

|

Matrix Mixer II

The matrix mixer circuit

described above can be modified to obtain polarizer function for the

controls. This means that zero level appears at the center position,

positive levels appear clockwise from center (addition), negative levels

counterclockwise from center (subtraction). An

(optional) switch is used for each column to select between normal mixer

mode (same function as the matrix mixer above) or polarizer mode for

this column. If a multiple switch is used the complete unit can be

switched between normal or polarizer mode.

The typical values for the parts

used are the same as for the matrix mixer above. But the potentiometers

have to be linear types ! Otherwise the zero position is not the

center position. |

|

|

|

Manual Gate

|

Manual Gate

The left picture shows the

basic circuit of a manual gate. The 470 Ohm resistor serves as a short

circuit protector. Without this resistor the +12V supply would be

shorted to GND if a patch cable is inserted to the socket while

the button is pressed. The

right picture is expanded by a LED display that lights up while the

button is pressed.

|

|

|

|

Or-wired sockets

|

Or-wired sockets

The left picture shows the circuit of

"or-wired" sockets. This circuit is useful to combine gate or

trigger signals. The incoming signals are or-wired, i.e. if any of the

inputs is "high" the output turns "high" too

("high" means a positive voltage in the range of typical

+5...+12V). If none of the inputs is high the 10k pull-down resistor

pulls the output to GND, i.e. "low". For most applications

this resistor is not required as the input load of the following module

acts as pull-down resistor. But it should be added to be on the safe

side. As a

modification of this circuit even "and-wired" sockets can be

realized. But this type of combination is not used very often: all

inputs have to be "high" to turn the output to

"high". For all other conditions the output remains

"low". On this the diodes have to be flipped (i.e. the

cathodes at connected to the input sockets) and the resistor has to be

connected between the output and +12V (so-called pull-up resistor). In

addition the switching contacts of the input sockets have to be

connected to GND (normalled to GND). This measure is necessary in order

that unused sockets read "low". Otherwise unused sockets would

read "high" because of the pull-up resistor. For

example a multiple A-180 can be modified with 7 additional diodes and

one resistor to obtain seven or-wired sockets and one output socket. For

this the pcb tracks between the eight multiple sockets have to be

interrupted (not the GND connections, only the "hot"

connections) and re-wired with the diodes and the resistor.

|

|

|

|

Non-inverting power amplifier

This is a simple non-inverting

power amplifier that can be used to drive loads like light bulbs,

LED bars, fairy lights, motors, magnets, relays or other loads.

Pay attention that the connected load is suitable for 12V supply

voltage. Otherwise the supply voltages of the operational

amplifier and the power transistors have to be adapted. If only

positive output voltages are required Q2 can be omitted. If an

operational amplifier is available in the preceding module (e.g. a

mixer A-138) this operational amplifier can be used and only Q1,

Q2 and R3 have to be added. The maximum output current depends

upon the specifications of the power transistors. Pay attention

that the power supply has to be able to deliver the additional

load current ! For higher currents (~ beyond 100mA) the

transistors have to be mounted on suitable heat sinks. Attention:

The output is not short circuit protected. If a standard

A-100 jack socket is used the output connection has to be

established before power is turned on ! During the

insertion of a plug into the jack socket a short circuit is made

for a short time. Therefore another type of socket is recommended

for the output (not the jack socket shown in the picture).

If only positive voltages

referenced to GND are required (e.g. to drive lamps, LEDs, motors and so

on) the circuit becomes very simple: In this case only Q1 is required

and R3 can be omitted (i.e. the base of Q1 is connected to the output of

the OpAmp, the collector of Q1 goes to +12V and the emitter is the new

"power output" - this circuit is called "emitter

follower"). This circuit can be used with all module outputs. In

our A-100 demo system an A-183-2

Offset Generator/Attenuator/Polarizer, that has been modified in this

way (i.e. only Q1 = BD243C), is used to drive a LED strip that is glued

by means of a double sided self-adhesive tape to the upper front rail of

the case. The brightness of the LEDs can be controlled manually and/or

by a control voltage (e.g. an ADSR which is is sync with a running

sequence). A picture of the A-183-2 with LED strip will follow

soon. |

|

|

|

4. Module

modifications

|

|

4.1. General modifications (not

for one module only)

|

|

4.1.1. Changing the sensitivity of manual

controls, control voltage inputs and audio inputs

|

|

The following picture shows the control

voltage input circuit for most of the A-100 modules:

|

|

P1 is the manual control of

the corresponding parameter (e.g. tune for a VCO, frequency for a VCF,

manual gain for a VCA, manual phase shift for a phaser and so on). P1

generates the voltage U1.

J1 is the (first) input socket for the external control voltage. P2 is

the corresponding attenuator. The slider of P2 outputs the voltage U2.

Additional CV inputs with our without attenuators may be available (e.g.

two or more CV inputs for frequency control for a VCF). The dashed line

in the picture is the common point in the circuit where all CV's are

added.

The output voltage of the circuit (output of O1) is used to control the

corresponding parameter (tune, filter frequency, gain ...) of the module

in question. The output voltage is defined by:

R3/R1 * U1 + R3/R2 * U2

The relations R3/R1 resp.

R3/R2 determine the sensitivity of the corresponding control (P1) resp.

input (J1/P2). If for example all resistors are 47k (a common value in

the A-100) the sensitivity is 1 for each input. Provided that R3 remains

unchanged the resistors R1 and R2 determine the sensitivity of the

corresponding control resp. input. Reducing the resistance of R1 resp.

R2 increases the sensitivity of the manual control (P1) resp. input

(J1/P2). Increasing the resistance of R1 resp. R2 reduces the

sensitivity. To modify the

sensitivity of a control knob (P1) or CV input (J1/P2) the corresponding

resistor R1 resp. R2 simply has to be changed.

Changing the resistance of R3 has the opposite effect and affects the

sensivity of both the manual control and CV input.

|

|

The audio input circuit for most A-100

modules is similar but the manual control P1 is absent (a DC offset

would not make sense for an audio input, audio signals are AC signals).

Normally only one audio input is available but there are exceptions

(e.g. VCA A-130 and A-131, signal processor A-109). To change the

sensitivity of an audio input simply the resistor R2 connected to the

slider P2 of the audio input has to be replace. A smaller value will

increase the sensitivity and consequently lead to clipping/distortion

for higher input levels. Especially for the first A-100 VCFs and VCAs

(A-120, A-121, A-122 and first versions of A-130, A-131) the

audio inputs have been designed to avoid distortion with standard A-100

signals (e.g. VCO). Lowering the input resistors will allow distortion

for these moduls too.

Even the input resistors of CV or audio

mixers (e.g. A-138a/b) can be changed to allow "real"

amplification (i.e. > 1). The factory values of the resistors in the

mixer modules A-138a/b allow a maximum amplification of about 1 (which

is not really amplification). Reducing the input resistors (R2 type) or

increasing the feedback resistor (R3 type) will increase the

amplification of the circuit.

The factory values of the corresponding

resistors (R1, R2, R3) for all modules can be found in the A-100 service manual.

Normally they are in the 100k range (~ 47k...220k).

|

|

|

|

4.1.2. Insert sockets for external

resonance control of filters, phasers and similar modules

|

|

To enable voltage control of resonance for

filters insert sockets in the feedback loop can be used.

|

|

The left picture shows the

resonance control in a filter or phaser circuit. Essentially it is an

attenuator that controls the feedback of the circuit. To enable external

control of the resonance external access to the feedback loop is

recessary.

For resonance control normally C-law potentiometers are used (i.e.

inverse logarithmic, e.g. 47kC).

|

|

|

|

|

This is the first solution

how to install the insert sockets (pre resonance control). J1 is

connected to the slider of the resonance control. Provided that no plug

is inserted into J2 the function of the module is unchanged as the

switching contact of J2 is active. As

soon as a plug is inserted into J2 the default connection is interrupted

and the signal fed to J2 is used as feedback signal. Consequently J1 and

J2 can be used to insert e.g. an external VCA to control the resonance.

J1 has to be connected to the audio input of the VCA, J2 to the audio

output of the VCA. The resonance control can be used to adjust the

maximum resonance available with different gain settings of the external

VCA. But not only a VCA but any audio processing module can be inserted

into the feedback loop (e.g. phaser, spring reverb, waveshaper, limiter, wave

multiplier, divider, ring modulator, frequency shifter, or even another

filter).

|

|

|

|

|

This is another solution how

to install the insert sockets (post resonance control). The

location of the resonance control at the pc board for all modules in

question can be found in the A-100 service manual.

|

|

|

4.1.3. Changing between AC and DC coupling

|

There are two types of coupling between

electronic circuits:

-

AC coupling (alternate current)

-

DC (direct current)

AC coupling means that only the AC

parts of the signal will pass. For this normally a capacitor is used

that connects the two circuits. The minimum value of the capacitor

depends upon the lowest frequency (f) that has to be transmitted and the

input/output impedance (R) of the two circuits. The approximate formula

for the minimum capacity is C ~ 1/(R*f) with f = lowest frequency, R =

in/output resistance

Example: minimum frequency = 50Hz,

in/output resistance = 10kOhm -> C ~ 2 uF (u = micro = 1/1000000). A

usual value would be 2.2uF in this example.

AC coupling is normally used for audio

signals. For audio signals AC coupling has the advantage that unwanted

DC shares in the signal are removed. For some AC processing circuits

(e.g. amplifiers, filters) DC voltages are not allowed in the input

signal. Therefore very often a capacitor can be found in the input stage

of such circuits.

DC coupling means that both DC and

AC parts of a signal are transmitted. For control voltages (normally)

only DC coupling can be used as even fixed voltages (e.g. coming from a

manual control) have to be transmitted.

In a module patch each A-100 module can

be treated as an electronic circuit that is connected to another one.

Consequently one has to take into consideration the type of coupling (AC

or DC) between modules as the strict differentiation

between AC and DC applications os softened for some A-100 modules. E.g.

a VCA can be used to process audio signals (i.e. normally AC coupled

signals) as well as slowly changing CV voltages (e.g. envelope or

modulation amount). Therefore one needs to know if a VCA used is AC or

DC coupled. Another example is a divider (e.g. A-115

or A-163) as even these module can be used to

process audio or (slow) clock/gate signals.

|

|

Luckily it is not very

complicated to switch between AC and DC coupling. All one has to do is

to bride (i.e. short circuit) the capacitor in case of an AC coupled

in/output. The left picture shows how

the switch is connected in parallel to the AC coupling capacitor (the

broken line resistor symbol represents the load to GND that is always

available in each circuit as reference to GND). If AC coupling is

required for a DC coupled in/output simply a capacitor has to be added. From

the schematics it can be seen if an in/output is AC or DC coupled. We

will add this information also to the user's manual for modules that may

be used for both types of coupling. For

some circuits resp. modules changing from AC to DC coupling is not

possible. E.g. the "old" VCAs A-130 and A-131 (those with

CEM3381 or CEM3382) are AC coupled as the special CEM circuits cannot be

DC coupled because of the internal negative reference voltage. The

"new" VCAs A-130 and A-131 (those with CA3080) are DC coupled

and can be used to process CV signals too. A

list with the type of coupling for all modules in question will follow

soon. For most of the modules the question about the type of coupling does

not arise. E.g. all filters are AC coupled and all CV generating and

processing modules (e.g. ADSR, LFO, slew limiter, Theremin, Ribbon

controller, random voltage) are DC coupled. But for other modules the

type of coupling is not obvious (e.g. VCA, divider, waveshaper).

|

|

|

4.1.4. Subsequent bus normalling of modules

|

Only a few modules (typically VCOs, envelope

generators or Midi interfaces) feature access to the CV and Gate signal of the A-100

bus. For details please refer to the information about the module in

question. General information about the CV and Gate signals of the bus

are available in the A-100

FAQ section.

If another module has to be modified accordingly.

Examples:

- rectangle output of an LFO to

"write" the LFO rectangle as gate signal to the bus gate

- gate input of the A-143-2 Quad ADSR from the bus gate

- CV input of a filter from the bus CV

|

|

The left picture shows the pin out

of the bus. The signals Gate and CV are available at the two

upper pin pairs of the bus (left and right pins are always

connected on the bus board and carry the same signal).

One has to distinguish between

two types of modules (the bus connector is always 16 pin):

- modules with 16 pin male bus

connectors

- modules with 10 pin male bus

connectors

If the module in question is

equipped with a 16 pin male connector both signals CV and gate

are available at the upper two pin pairs of the modules bus

connector. One simply has to wire the corresponding pin (one of

the upper pair for Gate, one of the second pair for CV) of the

16 pin connector to signal in question (e.g. to the rectangle

output of a LFO or to the gate input of an VCADSR or VC Decay).

|

|

|

|

If the module in question is

equipped with a 10 pin male connector the signals CV and gate

are not available at the modules bus connector. In this case a

special bus cable has to be used. The left picture shows how

this works. A 16 pin ribbon cable with a 16 pin female connector

on one side and a 10 pin female connector on the second side is

used. The 10 pin female connector is used to establish the

connection between the module and the bus. It is put to the

module's 10 pin male connector. The wire of the 16 pin ribbon

cable that corresponds to Gate resp.CV of the bus is connected

to the corresponding input (e.g. gate in, CV in) or output (e.g.

rectangle out) of the module. The wires #15 or #16 are gate, the

wires #13 or #14 are CV. The red marked wire is the bottom wire

that leads -12V (same for all modules).

Pay

attention that only one module is allowed to "write"

to the same bus signal. If two or more modules write

to the bus this leads to a short circuit of the corresponding

outputs.

The bus board has available two

jumpers (located in the middle of the bus board). If these are

removed the gate and CV lines are divided and both the left and

right part of the bus board are separate bus areas concerning CV

and gate. The power supply lines (-12V, GND, +12V, +5V) are

always connected and cannot be interrupted.

If more than three VCO CV inputs

are connected to the same bus the Bus

Access Module A-185 is recommended to write to the bus.

Otherwise signal losses may occur and lead to scaling problems. |

|

|

|

|

|

4.1.5. Subsequent socket normalling of modules

|

|

coming soon ....

(how to make use of unused switching

contacts of sockets for module pre-patching)

|

|

4.2. Specific modifications for

certain modules

Important note: Warranty

is void if these modifications are carried out by the customer !

|

|

4.2.1. A-128 filter bank modification: single outputs

|

|

This document shows how to add single

outputs to the filter bank A-128: A128_single_outputs.pdf

|

|

|

4.2.2.

A-136 Modification: bypassing the internal pre-amplifier

|

Module A-136

contains an internal pre-amplifier that is used to amplify the input

signal by about 3.5 before it is processed by the A-136. Especially for

low level audio signals (e.g. output from a VCF) this is useful. But for

all signals with a level beyond ~ 7V this causes clipping before the

internal processing takes place. Especially for the processing of LFOs

or unfiltered VCOs this may cause a problem. To bypass the internal

pre-amplifier resistor R2 has to be removed (e.g. by

pinching off). R2 is the resistor in the upper third of the pcb which is

very close to the rear edge. When R2 is removed the amplification of the

internal pre-amplifier becomes "1" (which means that it does

no longer amplify).

In addition one has to pay

attention that the knob positions may vary a bit from the front panel

printing because of mechanical tolerances of the potentiometers and

knobs (i.e. "0" is not always exactly the neutral

position for "A", "+A" or "-A")

|

|

|

4.2.4. A-151 Modification: switch for

limiting the number of steps (only for old versions of A-151)

|

A toggle switch 1-0-1 type is required (i.e. with center

position). A hole for the additional switch can be drilled e.g. below

the socket I/O4.

This is how the switch has to be wired:

- terminal 1 to CD4052 pin 11 (= LED control for I/O 2)

- center terminal to reset input via a standard diode (e.g. 1N4148),

cathode (-) on reset, anode (+) on switch terminal

- terminal 2 to CD4052 pin 15 (= LED control for I/O 3)

The new version of the A-151 is already

equipped with this switch. Thank's to Peter Grenader for this idea.

|

|

|

4.2.5. A-148 Modification (old version):

T&H instead

of S&H

|

|

The new version of the Dual S&H module

A-148 has a jumper available for each sub-unit that is used to set the

operation mode for the corresponding sub-unit to S&H or T&H. The

old version of the A-148 was fixed to the S&H mode. To make

available T&H for the old version of the A-148 one has to replace

the capacitor C1 (10nF) by a resistor (about 1k). C1 is available twice

on the pc board: one for the upper and one for the lower unit. It is

also possible to add a switch that is used to switch between S&H

(capacitor) and T&H (resistor).

|

|

|

4.2.6. A-152 Modification: S&H instead

of T&H

|

Normally the eight S&H outputs of the

module A-152 work not as S&H but as T&H outputs (details can be

found in the A-152 user's manual). To obtain S&H function instead of

the T&H function the module has to be modified in that way:

A connection has to be made between pin 6 of the microcontroller IC1 (on

board A, PIC16F676) and pin 2 of IC6 (on board B, DG408). The 10k

resistor R32 next to C5 on board B has to be removed. And that's how it

works: the enable pin of the multiplexer DG408 is normally connected to

+12V ("high") via resistor R32. Pin 6 of the microcontroller

(RC4) outputs a short high pulse whenever the address changes. If the

enable pin of the multiplexer (DG408) is connected to this pin (instead

to +12V via R32) the T&H function changes to a S&H function as

the multiplexer is enabled only for a short time at each address change.

Even a toggle switch that selects the

desired mode can be connected to the pins and the resistor.

|

|

|

4.2.7. A-155 modifications/undo

modifications: gate reset, manual step debouncing

|

|

This document shows how to modify or undo

the modifications of the sequencer module A-155: A155_Modifications_Undo.pdf

There are two possible modifications:

Modification #1 refers to the behaviour

of the gate row. Without this modification the gate output remains

"high" if the sequence stops at a position with the

corresponding gate switch in the on position. If this modification is

carried out the gate outputs turns "low" as soon as the

sequence stops. It's an AND wiring of the gate outpout with the

start/stop state of the A-155. If the A-155 is combined with the A-154

this modification has to be removed ! Modification

#2 is a debounding circuit to avoid multiple triggering if the manual

step button is used. This modification limits the maximal clock

frequency to some hundred Hz (digital low pass). For normal sequencer

applications this is no restriction but if the A-155 is

used e.g. as a graphic VCO the modification has to be removed. It is not

necessary to remove this modification if the A-155 is combined

with the A-154.

|

|

|

4.2.8. A-155 Modification: changing gate

row into trigger row #4

|

The factory setting of

the function of row #4 of the trigger board is Gate. If

one prefers another Trigger row the following modification

has to be carried out:

The connection marked by the arrow in the picture has to be interrupted.

Instead of this a connection between pin 5 of IC2 (CD4053) and the

close-by pcb track has to be installed (solder jumper).

|

|

4.2.9. A-155 Modification: adding

sockets for address outputs

|

|

This is the pinout of the internal 10 pin

connector that leads from the small control board to the potentiometer

and switch boards:

Besides the supply terminals (-12V, GND,

+12V) these signals are available:

- Address signals A0, A1, A2

- Clock signal

The A-155 control board includes a simply

binary counter (CD4024) that generates the address signals (A0, A1, A2).

The advance of the binary counter to the next address is triggered by

the clock signal. The control boards outputs the three address signals

and the clock signal. The potentiometer and switch boards receive these

signals. The signals have CMOS levels (~ 0/+12V) as the CMOS circuits of

the control board are 12V powered. They are not TTL compatible ! A

simple solution to have the address signals A0, A1 and A2 and the

internal clock signal available for other modules the corresponding pins

of the control board can be connected to sockets via protection

resistors (typ. 1k). A better solution is to insert suitable buffers

into the outputs. It's also possible to feed the potentiometer and

switch boards with other address and clock signals than those coming

from the A-155 control board. The signals have to be 12V CMOS compatible

(i.e. low = 0V, high = +12V).

All modifications should be carried out by experts only as the modules

contain charge sensitive devices. We have to point out that warranty is

lost if such modifications are carried out.

|

|

|

4.2.10. Modifying the A-124 Wasp Filter

for self-oscillation

|

|

Soldering a 10k resistor in parallel to R13

(27k) leads to self-oscillation of the filter at the max. resonance

setting of the resonance control. R13 is located in the gap between IC1

(CD4069) and IC2 (i.e. the upper CA3080, close to C4/100pF).

(Thanks to Pierre

Serné for the permission to publish this picture)

|

|

|

4.2.11. Modifying the A-163 voltage

controlled frequency divider for DC coupling

|

|

Shortening the electrolytic capacitor C7

(2u2) changes the output from AC to DC coupling. C7 is located between

the input and the output socket After this modification the A-163 can be

used e.g. for frequency dividing of LFO signals too (only suitable for

rectangles). Instead of the short circuit even a switch can be used that

switches between AC and DC coupling. The only difference between AC and

DC coupling is that in the DC coupled mode the output rectangle switches

from GND to ~ +5V while in the AC coupled mode the signal is

symmetrically around GND (~ -2.5/+2.5V). Usually even the DC coupled

mode can be used for audio signals as most of the audio processing

modules (e.g. filters) have an AC coupled audio input that removes the

positive offset of the A-163 output in DC coupled mode.

|

|

|

4.2.12. Modifying the A-165 trigger

inverter/modifier for S-Trig input

|

|

This document shows how to modify the

trigger modifier/inverter for S-Trig input: A165_strig_modification.pdf.

The modification is very simple. Just one 100k resistor has to be added

between the input socket and +12V.

|

|

|

4.2.13. Shortening the output protection

resistor of A-156, A-170 and other modules

|

Most of the A-100 modules are equipped with

a 1k protection resistor at the output. This resistor protects the

output of the module against shortening to GND or shortening to another

output. In sensitive CV applications (typically driving the CV input of

one or more VCOs) these protection resistors may cause a small voltage

drop that leads to inaccuracy in the 1V/Oct scale. There are two

solutions:

- Usage of a CV buffer between the

output of the A-156/A-170 and the VCO input(s), e.g. A-185-1

or A-185-2)

- Shortening the output protection

resistor

If the protection resistor is shortened

the output is no longer protected against shortening to GND or another

output but the voltage drop caused by the protection resistor is

eliminated. For the A-170 the protection resistor is R2 (positioned

below the imprint "A-100 MODULAR SYSTEM" on the pc board. For

the A-156 the resistors are R17 and R20 (above and below the upper

integrated circuit IC3/TLC274).

|

|

|

4.2.14. Removing the springs of the A-174

joystick module

|

|

Method #1: Bend very carefully the four metallic

tongues of the corresponding potentiometer that hold the end plate of

the potentiometer in question. E.g. a small screw driver could be used.

Pay attention not to break off the tongues. Then the end plate and the

spring can be removed. Re-install the end plate by bending back the four

tongues. This can be done for both or only one of the two potentiometers

of the joystick.

Method #2:Another possibilitly is to compress the two ends of

the spring and cut with a suitable small cutting pliers without

dismantling the potentiometer. In this case the remnant of the spring

remains in the potentiometer.

Pay attention that warranty is lost if the

joystick is modified !

|

|

|

4.2.15. Meaning of the pin headers of the

A-174-2 wheel module

|

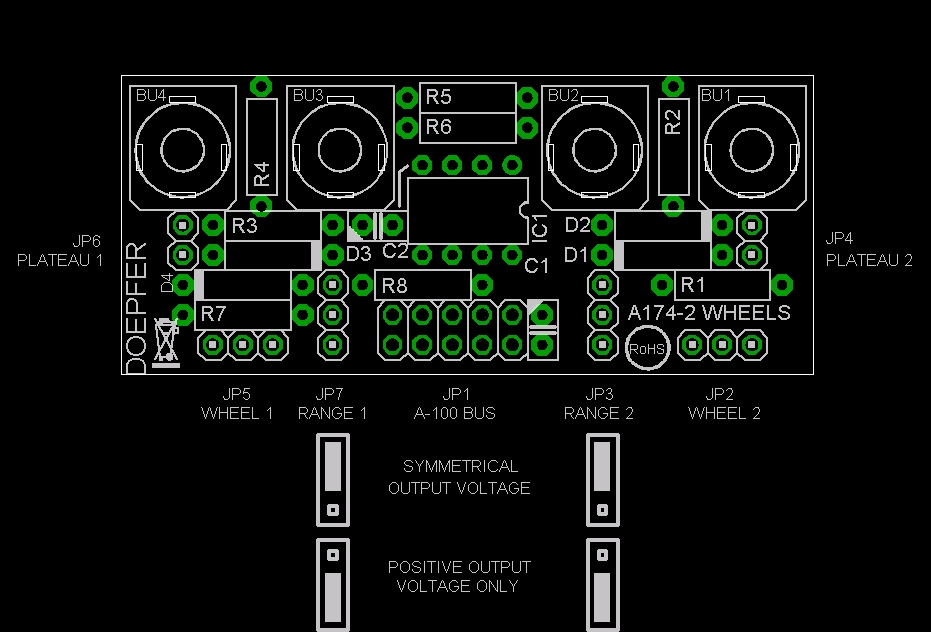

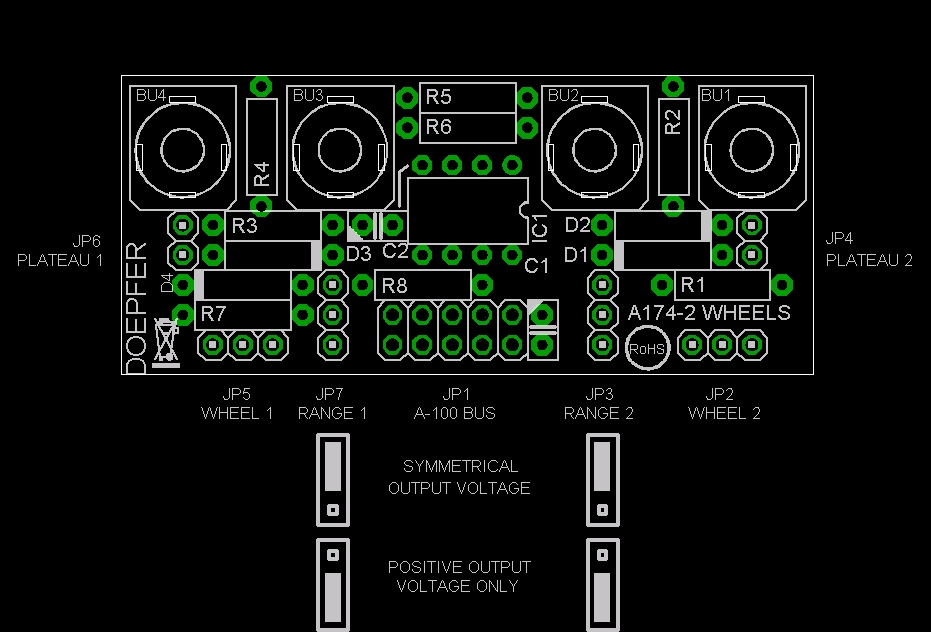

The jumpers JP4 and JP6

are used to install a small voltage plateau around 0V. The plateau

appears if the corresponding jumper is removed (normally used for the

spring loaded wheel only to obtain 0V output in the neutral position).

The jumpers JP3 and JP7 are used to select the output voltage range

(i.e. symmetrical or positive voltage only). Pay attention that this

corresponds to the mechanical adjustment of the wheels ! This means one

has to re-adjust the wheels also if the jumper settings of JP3 or JP7

are changed. That's a bit tricky and only recommended for experienced

users. Otherwise the voltage range of the outputs will be not correct

(e.g. not starting with 0V or a large "dead range" for the

wheel without spring, or not 0V in the center position of the spring

loaded wheel).

Pay attention that

a re-adjustment of the wheels liable to pay costs if the

wheel adjustment has been changed by the customer !

|

|

4.2.16. Changing the BBD circuit in the

A-188-1 BBD module / Adjustment of the A-188-1 BBD module

|

|

The following document

describes the A-188-1 adjustment procedure: A1881_adjustment.pdf

|

|

|

to be continued

|

|

|

5. Simple DIY modules

/ frames

|

|

5.1. Attenuator

|

|

This is the simple

attenuator circuit mentioned in chapter 2. The two sockets J1 and J2,

and the potentiometer P2 can be mounted on a blind panel with 8 HP (4 HP

will be a little to small for the potentiometer). To take advantage of

the whole 8 HP panel a second attenuator or a small multiple (i.e. some

connected sockets) can be mounted on the same panel. A value of 50k is

recommended for P2 (linear for CV applications, log for audio

applications).

|

|

5.2. Bypass / Bypass with attenuator

|

|

The left circuit is a simple

bypass that can be used to decide if an audio processing module (e.g. a

filter or a phaser) is active or not. J1 and J2 form a miniature

multiple. J1 is connected to the audio source (e.g. a VCO output or a

mixer output), J2 to the audio input of the audio processing module

(e.g. filter). J3 is connected to the audio output of the processing

module. The position of the switch determines if the audio processing

module is active (lower position of the switch) or not (upper position

of the switch). The four sockets and the switch can be mounted on a

blind panel with 4 HP. In

the right circuit the bypass is expanded by two attenuators (P1, P2)

that can be used to compensate possible audio level differences, i.e. no

or little audio level changes appear when the switch is operated. One of

the attenuators may be omitted if not both levels have to be adjusted.

The four sockets, the two potentiometers and the switch can be mounted

on a blind panel with 8 HP. 50k log is recommended for P1 and P2.

|

|

|

|

5.3. Self-construction

of A-100 frames

|

|

The left picture shows the

construction of the standard 6 HU A-100 frame (A-100G6). The

construction is described in detail in this document:

The standard 6 HU frame is

made of the following components:

-

(1) front rail version 1 (with lip), with threaded inserts (for

module mounting)

-

(2) front rail version 1 (with lip), with slide nuts (for rear

covers mounting)

-

(3) front rail version 2 (without lip), with slide nuts (for bus

board mounting)

-

(4) front rail version 2 (without lip), for increasing stability

only

-

(5) side plate

-

(6) 19" mounting flange

-

(x) top and bottom cover

(not shown in the picture)

A detailed description of

the A-100 frame construction is available as pdf document A100G6_e.pdf The

most expensive parts of the frame are the side plates, mounting flanges

and top/bottom covers. If you do not care much for a 19" compatible

housing a low cost version of an A-100 frame can be built according to

the following instructions. Pay attention that this is suitable for qualified personnel only who are able to

ensure the electrical safety of the final construction. On no

account beginners or laymans are allowed to assemble frames. Dangerous

mains voltage 115V / 230V. Danger to life !

|

|

|

|

|

From the parts list above

only the front rails version 1 with "lip" and threaded inserts

(1) and the accessory screws are required (the screws that are used to

mount the rails to the side plates in the standard version of the

frame). Around these 4 rails a suitable case has to be constructed as

outlined in the left picture. The rails and accessories are available from the

German company ProMA (www.proma-technologie.de)

but there are many other companies on the market too. Even rails longer

than the 19" standard can be used to obtain bigger non-19"

frames (from ProMA e.g. rails with 1m length are available). At

the rear of the case the A-100 power supply (A-100NT12 or A-100PSU2,

with mains inlet, power switch and fuse holder) and the bus boards have

to be mounted with distance sleeves or spacers. The wiring of the power supply and the bus boards is described in

this document:

As these works affects parts, pc boards and cables that conduct mains voltage

(230/115V) carrying out of these works is allowed only for experts or authorized

personnel who are familiar with all valid safety rules. Laymen are not

allowed to carry out these works ! Danger to Life.

|

|

6. Miscellaneous

|

|

6.1. A-100 Power Supply

|

|

The A-100 requires a bipolar/symmetrical

power supply with -12V, GND and +12V. A high quality linear

power supply is recommended. Switching power supplies are not

recommended. We tried several switching power supplies for A-100. The

main advantages of switching power supplies would be the wide range AC

input (typ. 90-240V AC, i.e. no supply modification if you move e.g.

from USA to Europe and vice versa), low price and small shape/weight. As

some customers suggested switching supplies we ordered three types of

switching supplies with different power (Meanwell, Sun Power, Condor/SL)

and installed them into standard 6U/84HP cases and a 12U/168HP monster

case. For all tested supplies the results are very poor. The main

problem is the unsufficient load regulation that may lead to VCO tuning

problems. We found up to 200 mV (=0.2 V) voltage change of the +/-12V

supplies while the load changes. Such load changes are caused e.g. by

different LED illuminations (normally a module will consume more current

if a LEDs is bright compared to the dark state) or other effects (e.g.

frequency changes of VCO/VCF). If the linear A-100PSU2 was used the

+/-12V changed only by about 5mV under the same conditions. Consequently

switching power supplies can be recommended only for

"non-critical" DIY applications (e.g. if only CV

sources/modifiers and audio modifiers are installed). For frames that

include one or more VCOs we recommend the A-100PSU2 or another linear

supply with good load regulation (10 mV or better).

|

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()